Hunter Pumps Industrial, a leading supplier of industrial pumps in Australia for over 25 years, offers a range of progressing cavity pumps known for their constant flow rate and suction lift capability. These pumps are perfect for positive displacement process applications, including pumping food and drink products, sewage, oil, viscous chemicals, wastewater sludge, slurries and other fluids. Committed to the highest quality, our cavity pumps are designed to meet the most demanding industrial requirements.

Progressive cavity pumps, also known as helical rotor pumps or cavity pumps, are a type of rotary positive displacement pump with a single-threaded helically shaped rotor turning inside a double-threaded helically shaped rubber stator.

Typically used in industries for pumping shear sensitive polymers, thick sludge and handling highly viscous fluids like crude, grease, lubricating oils, heavy fuel, and bunker fuel. They excel in dosing, metering, drum emptying, and hygienic applications.

The rotor, a helical-shaped worm component, rotates within the stator, a flexible material, creating temporary chambers where fluid is drawn, forming a ‘worm thread’ or progressing cavity. The flow is directly proportional to speed, making them ideal for metering fluids and handling slurries, shear sensitive or two or tri phase mixtures in both low to high flow applications.

The development of multi-stage pumps has increased their pressure handling capabilities, enabling them to effectively transfer liquids of different compositions.

A progressive cavity pump works through a helical rotor rotating inside a double helical hole, forming a screw-shaped rotor within a stationary stator. As the rotor spins, it creates cavities containing fluid that result in a continuous flow. Progressive cavity pumps transport fluid through cavities created when the rotor seals tightly against the stator during movement.

The pumping element comprises a precision-machined metallic rotor with a single helix rotor and an elastomer stator with a double internal helix. These pumps consist of numerous consumable parts, including a rotor and stator set, coupling, drive shaft, and mechanical seal, all designed with precision to ensure efficient operations despite tight tolerances.

They can handle both abrasive and viscous fluids, with the latter also serving as a lubricant for internal parts, ensuring a long and reliable life. The metal rotor’s rolling action in the resilient stator quickly releases trapped solids, reducing abrasive wear.

Progressive cavity pumps are versatile and used across all industrial applications to pump a wide variety of thin and thick liquids, be it corrosive or solids-laden. As progressive cavity pumps can handle difficult, thick, solid-laden liquids, they can often be used in applications where no other pump would perform.

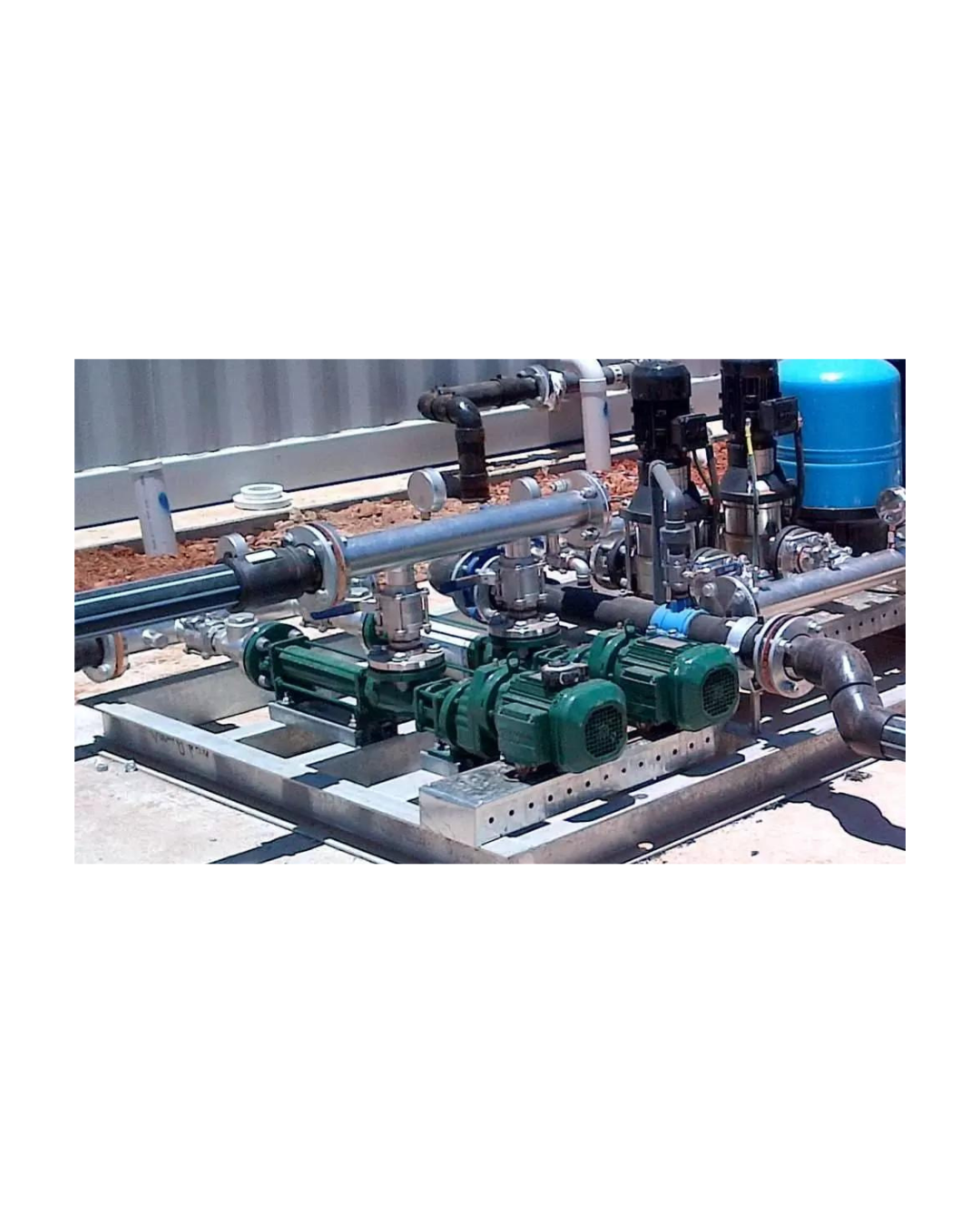

At Hunter Pumps Industrial, we offer a wide range of Centrifugal Pumps and Positive Displacement Pumps from the world’s most trusted manufacturers. Our progressive cavity pumps are designed to self-prime and suction lift as the rotor rotates, progressing towards the discharge end of the pump. They are suitable for low and high-flow applications and can pump fluids without contamination.

Spare parts are readily available for emergency cases. Our trained and experienced staff can be dispatched quickly for effective pump servicing. Reach out to us today for your pumping needs.

Get in touch with Hunter Pumps to schedule your free pump assessment

Contact Hunter Pumps today

No, a Progressive Cavity Pump (PCP) and a Screw Pump are not the same. While both move fluids, they vary in operation. A PCP uses a spiralled rotor moving within a stator, creating progressing cavities that push the fluid. In contrast, a Screw Pump utilises intermeshing screws to transport fluid.

No, progressive cavity pumps should not run dry. Dry running causes excessive friction and temperature, leading to stator damage and possible destruction of the pump itself. The loss of lubrication from the pumped fluid can also harm internal components and the motor, necessitating costly repairs and downtime. The measures must be taken to prevent dry running.

When choosing a progressive cavity pump, consider pump displacement, pressure or conveying distance, and the medium's physical and chemical properties (viscosity, temperature, abrasivity, corrosivity). Also, take into account flow changes, your budget, available installation space, environmental requirements, and the preferred installation method. These factors will inform your choice of material and processing technology for the pump. At Hunter Pumps, we'll help find the right progressive cavity pump for your needs. Consider all factors and let our expertise guide your choice. Talk to us.

Hunter Pumps stocks, sells, and services a wide range of progressive cavity pumps from leading manufacturers, including Wangen, Mono, Roto, and Netzsch. Our extensive brand selection ensures we can provide a pump to meet any industrial pumping requirement.

You can contact us by calling us at 02 4958 7555. Our specialist team is ready to work alongside you to identify and create the best mechanical solution for your needs, regardless of your budget or project scale.

Hunter Pumps: Your premier provider of industrial pump solutions.

Count on us for industrial pump repairs, preventative servicing, and regular maintenance of industrial pump systems.